IIn today’s fast-paced business environment, efficiency is key to staying competitive. One of the most effective ways to improve operational performance is by leveraging real-time data to monitor machines, processes, and equipment. Real-time data offers unprecedented visibility into your operations, enabling you to make informed decisions and respond quickly to challenges.

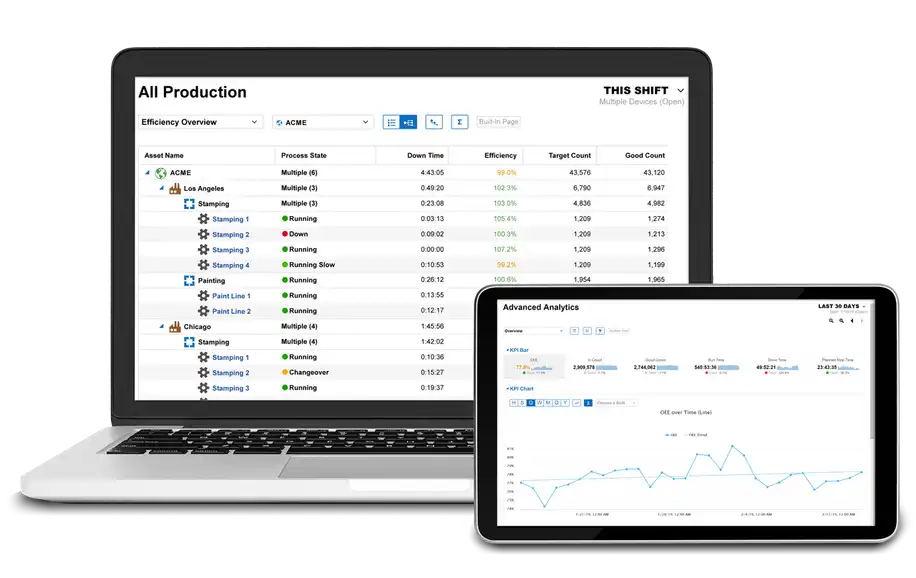

Real-Time Insights for Better Decision Making: Monitoring your machinery or processes in real-time allows you to gather up-to-the-minute insights on performance, status, and condition. By having this data at your fingertips, you can make decisions based on actual performance, rather than relying on outdated or estimated information. For example, if a machine is approaching a failure, real-time alerts can notify the team to take action before it leads to costly downtime.

Predictive Maintenance: Prevent Breakdowns Before They Happen: With real-time data, you can implement predictive maintenance strategies. By monitoring factors like temperature, pressure, vibration, or usage hours, you can detect early warning signs of potential failures. This means you can schedule maintenance activities based on actual wear and tear, reducing unexpected breakdowns and costly repairs. Predictive maintenance helps extend the life of your equipment and optimizes its performance.

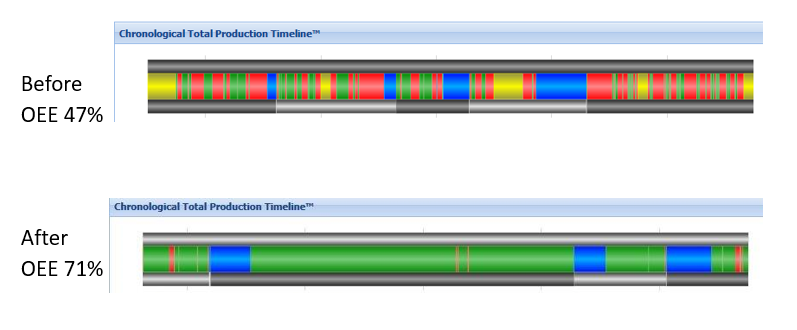

Enhanced Efficiency and Productivity: By continuously monitoring your machines and processes, you can spot inefficiencies that may not be obvious during regular operations. For instance, tracking the time a machine is idle, or comparing the output rate against industry benchmarks, helps identify areas for improvement. With real-time data, managers can instantly adjust workflows, make on-the-spot adjustments, and improve overall productivity.

Remote Monitoring: Control from Anywhere: The ability to monitor machines and processes remotely is a game changer. With IoT (Internet of Things), you can access your data from any location, at any time. Whether you’re on the factory floor or traveling for business, real-time data allows you to stay connected to operations, ensuring you can manage and troubleshoot without being physically present.

Data-Driven Continuous Improvement: Real-time monitoring is the foundation for continuous improvement. By consistently collecting and analyzing data, companies can spot trends and track performance over time. This ongoing data flow provides valuable insights that can drive operational strategies, optimize resource allocation, and lead to smarter decision-making.

For more information on Real Time Data, Lean Training and OPEX Support email us at info@smartleanmfg.com

Improving Operations with Real-Time Data: Monitor Any Machine, Any Process, Anywhere