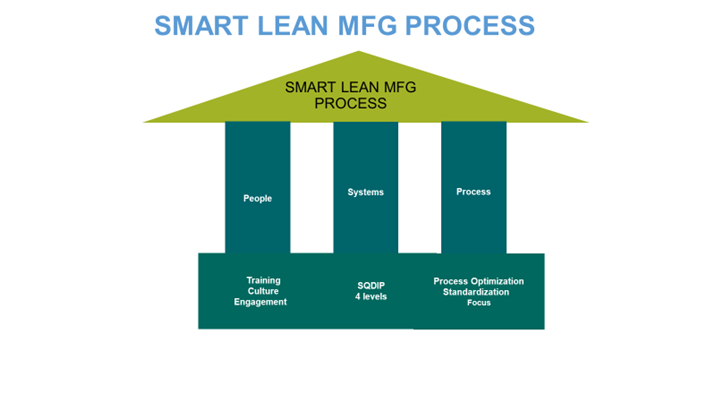

Systems and processes are important BUT Don’t forget your Employee!

“Tell me and I forget. Teach me and I will remember. Involve me and I will learn and support “ In today’s rapidly evolving global marketplace, numerous industries striving to satisfy increasing demands and stay competitive are turning to advanced production technologies as a means to achieve efficiency and innovation. Embracing these cutting-edge tools undoubtedly …

Systems and processes are important BUT Don’t forget your Employee! Read More »