Hands-on Operational Excellence Implementation Services

We provide hands-on Operational Excellence Implementation services tailored to organizations that may not have the capacity to hire a full-time expert

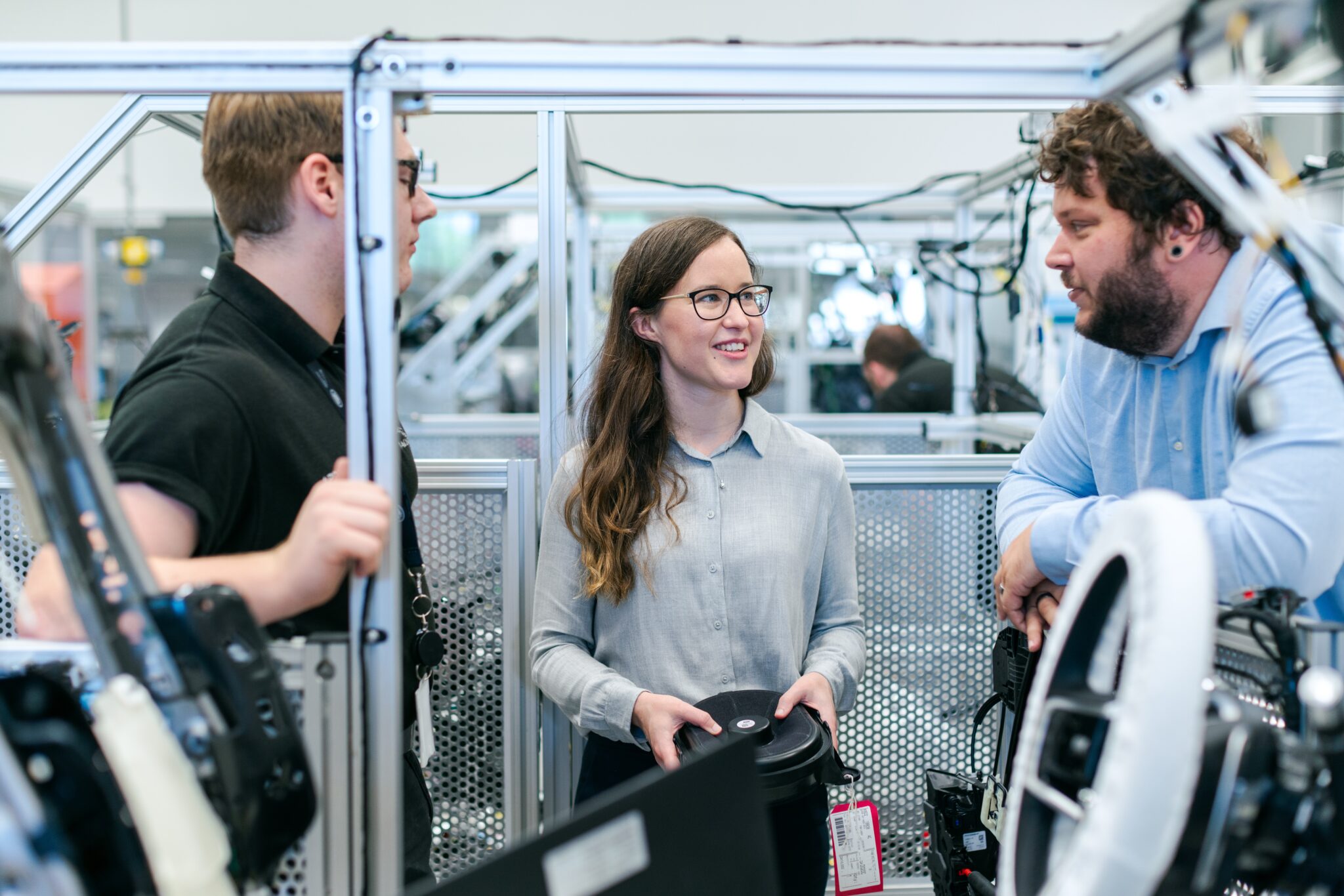

We help organizations enhance their operations and attain lasting outcomes by applying lean methodologies, improving processes, and utilizing intelligent manufacturing techniques. We assess, execute, train, and ensure continuity Implementation A to Z

Our philosophy, grounded in People, Systems, and Processes, focuses on the goal of increasing throughput and reducing operating expenses

YEARS

Kaizens

PROJECT

Operations & Lean Assessment

Real-Time Data and Monitoring

KPI, Daily Visual Management

Lean and TOC Training Centre

Quality – QMS ISO 9001:2015

Maintenance Management

Lean Transformation & Support

Process Engineering, Robotics & Support

Real Time Data & OEE Implementations

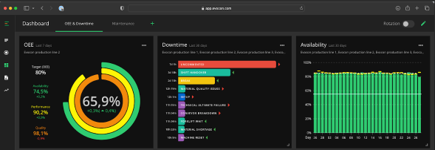

This process will empower your team to make real time data driven decisions. By installing and collecting real time metrics on production performance and output, you’ll gain unprecedented insights into your plant’s operations.

Our platform enables your teams to quickly identify and fix constraints that are hurting your plant’s performance, leading to improved efficiency and profitability.

With 24/7 access to insights and data at your fingertips, you can stay informed and act from any location. Our user-friendly platform makes it easy to track performance, identify trends, and monitor key performance indicators.

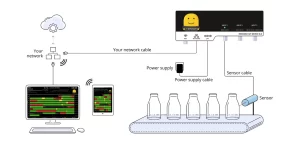

We also ofer Real-time cloud-based production monitoring system that enables manufacturers to:

- Automate and digitize machine data collection

- Get quick and intuitive insight into production performance

- Identify bottlenecks and improvement areas

- Increase equipment effectiveness

- Monitor production downtime, OEE, performance and quality

Our solution combines plug and play hardware and browser-based interface.

How OEE and SQDIP Boards Drive Daily Operational Excellence

Calgary Project – Increase OEE from 56% to 69% in 3 Months In today’s manufacturing

The Physics of Business Growth with Managing Boards

Success in business isn’t random—it follows a structured, data-driven methodology. By approaching business challenges like

The Importance of an Initial Lean Assessment

Implementing a Lean program without an Initial Lean Assessment is like setting off on a

Improving Operations with Real-Time Data: Monitor Any Machine, Any Process, Anywhere

IIn today’s fast-paced business environment, efficiency is key to staying competitive. One of the most